PRODUCTS & SERVICES

CONTACT FOR SERVICES

Therm- X Industrial Equipments Pvt. Ltd.

Mr. Joseph Thomas (Director) A-15/18, M. I. D. C., Butibori Nagpur – 441122, Maharashtra, India

Call Us :

09764551188

Telephone :

+(91)-(7104)-265839

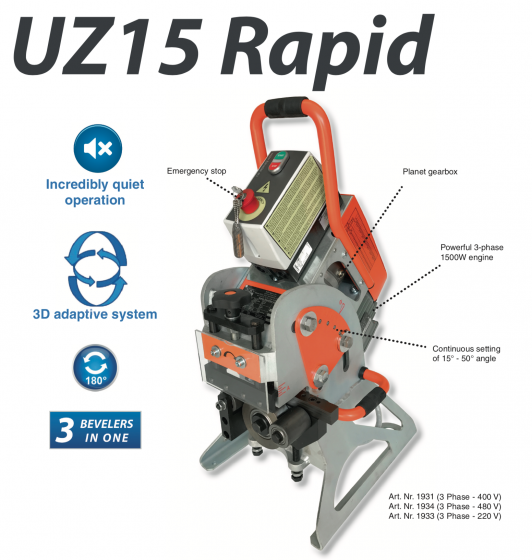

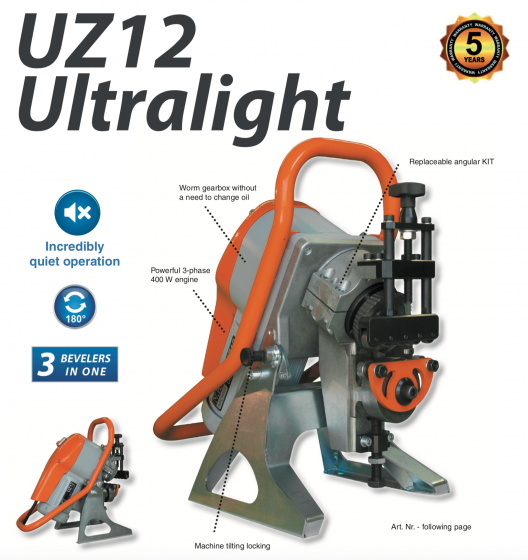

UZ-LINE BEVELING MACHINE

MACHINES | ITEM CODE:

Description:

- The UZ12 ULTRALIGHT is one of the lightest bevelling machines with the automatic feed in the market.

- Thanks to its compact size and low weight it is perfect not only for workshops but also for assemblies.

- The machine is equipped with the automatic feed. Working with UZ12 ULTRALIGHT is therefore very comfortable.

- The quietest bevelling system on the market.

Technical data:

- Max. bevel width: 12 mm / 0.47 in

- Bevel angle: 30°, 45°, 22.5°, 37.5°, 50° (replaceable KIT)

- Thickness of bevel. material: 3 – 35 mm / 0.12 – 1.37 in

- Engine: 400 W

- Feed: 1,8 m/min. / 5.9 ft/min.

- Weight: 30 kg / 66 lb

- Dimensions: 470 x 294 x 523 mm / 18.5 x 11.57 x 20.59 in

Description:

2 BEVELERS IN ONE + 3D ADAPTIVE SYSTEM = UNIQUE BEVELLING SOLUTION, MADE BY NKO MACHINES

- UZ15 RAPID creates welding-ready bevels on linear plates of any shearable material, including iron, steel (up to 85,000lbs/in² or 60kg/mm2), stainless steel, brass, copper and aluminium. It cuts bevels from 3/16 to 1-9/16″ (5 to 40 mm) in thickness, with a minimum plate width of 2-3/4″ (70 mm) and minimum plate length of 5-7/8″ (150 mm).

- The beveling angle adjusts continuously from 15° to 50° without replacing any parts. The pressure bar unit and the piece supporting unit can be adjusted in height and are supplied with visible graduated scales.

- It can be hooked to the piece to be machined in either a horizontal or vertical position. When used with the trolley, the machine can be inverted in order to bevel the bottom side of the plate. Both X and K bevels are possible.

- Easily attaches to trolley 180°

- Inversion allows for creation of a double-sided bevel – no need to rotate or flip heavy material

- Assembles or disassembles in seconds without tools with a unique clamping system – Lift handle on trolley adjusts machine to working height

- Functions as a stationary or a moveable station

- Package discount available when machine and trolley are purchased together

MANIPULATOR 3D

-

- maniulator provides a simple, quick turn the UZ15 RAPID of 180°for create double-sided bevels XK. The operator does not need a crane to rotate of material. There is a significant time saving at work.

- unique clamping system allows machine UZ15 RAPID assemble and disassemble (Quick System) within few seconds without using any tools. the beveler UZ15 RAPID is “floating” on MANIPULATOR 3D and compensates unevenness of the floor

- MANIPULATOR 3D allows easy manipulation with beveler

- required height of machine can be set up by MANIPULATOR 3D by lift handle

- travel is provided by massive wheels mounted on the carriage

- possibility to bevel with MANIPULATOR 3D or without

- possibility to use the MANIPULATOR 3D like stationary station

Technical data:

-

- Working range max. bevel: width (B): 15mm

- Bevel angle: 15°- 50°infinitely variable

- Thickness sherable materials: from 6 to 40mm

- Engine: 1500 W/ 2800 rpm/3,5m/min

- Machine weight: 94kg

- Dimensions: 530 x 395 x 860mm

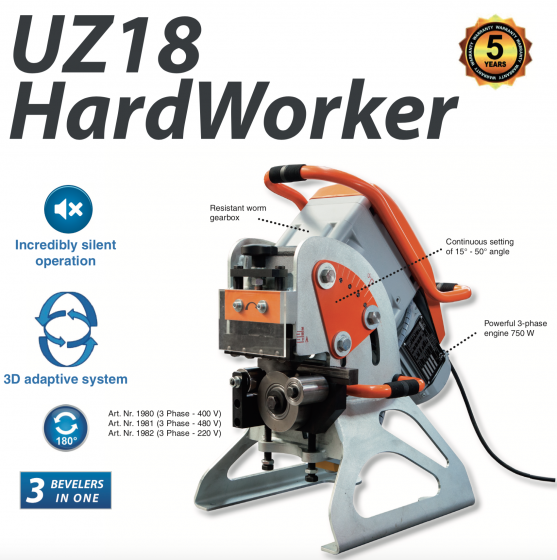

Description:

Double Sided High Speed Beveler UZ 18 HardWorker, variable angle adjustment (maximum bevel width 18 mm/0,70″. Automatic feed)

- For steel (strength up to 700 MPa), brass, copper and aluminium.

- For bevelling material with minimum dimensions – width 70 mm/2,76″, length 150 mm/5,91″, thickness 6 mm/0,24″.

- Thickness of bevelled material 6 – 40 mm/0,23″-1,58″.

- The bevel angle is easily adjustable from 15° to 50° – smoothly, without the need to replace any part.

- The equipment is capable of performing double-sided bevelling (X, K) without the need for material handling.

- Easy connecting to the 3D Manipulator for easier operation and handling.

- The machine is equipped with an automatic feed.

- The possibility of stationary and mobile use.

- The machine works on large workpieces without support.

- Smaller parts of the material are inserted directly into the machine.

- An advantageous price when purchasing UZ 18 Hardworker together with the 3D Manipulator.

MANIPULATOR 3D

- Unique MANIPULATOR 3D – unique design of the manipulator offers the possibility of a simple turning of the beveling machine by 180 ° for performing the X, K double-sided bevel. No tools required to rotate. No need for material handling = significant time savings.

- The quick-connect system offers the option to connect and disconnect the UZ 18 Hardworker from the 3D Manipulator within seconds without the use of any tools. You will appreciate this in a situation where the 3D Manipulator cannot follow the machine due to the poor quality of the working floor.

Technical data:

- Max. bevel width: 18 mm (600 MPa)

- Continuously adjustable angle: 15° – 50°

- Thickness of bevel. material: 6 – 40 mm

- Engine: 750 W / 380 V

- Feed: 1,9 m/min.

- Weight: 110 kg

- Dimensions (WxHxD): 43,8 x 71,9 x 64,4 cm

Item Code: UZ-20

Widely demanded in electrical industry, this Beveling Machine is presented in the market in numerous specifications. These beveling machines are finely finished with the use of updated technology based accessories. These beveling machines are damage proof.

Beveling Machine UZ 20 (max. width of bevel 20 mm):

Powerful, stationary beveling and deburring machine for the efficient beveling of flat steel, plates and profile material.

- For all carbon steels, cast iron, aluminum and light metal alloys, non-ferrous metals and all cuttable materials.

- The feed permits bevel machining without tight camping of the workpiece.

- The swiveling milling spindle permits a milling angle within a continuous range of 30° – 60°.

- Regulation of feed speed and cutting tool

- Option to buy additional accessories such a milling divider for pipes, table extension left and right (total 2800 mm) with adjustable side stops left and right

Applications:

- Parts that require preheating before welding in the automotive, rail and shipping industry.

- Pipe and flange – manufacturing, construction and repairs.

- Petrochemical industry – manufacturing, constructi- on and repairs.

- Preheating before hard surfacing, foundry.

- Heat exchangers, pressure vessels, flanges etc.

- Energy industry.

- Manufacture of steel structures.

- Mining equipment.

- Maintenance

Description:

UZ29 SPEEDER machine is one of the largest and most powerful machines in the field of rotary cutting bevelling machines.

The machine is equipped with an automatic feed and can be used as a stationary machine designed for large and small volumes of smaller workpieces.

At the same time it can be used as a mobile bevelling system when the machine moves along the machined steel sheet at a rare of almost two meters per minute.

The UZ29 SPEEDER machine is capable of machining both, standard and stainless steel.

The machine has a supersilent drive not increasing the noice at the workplace.

In addition it is possible to flip the entire machining unit upside down and create bevels for X and K form of the welds without handling machined material.

This application is made possible by the rotary mechanism of the 3D manipulator, which is a standard machine equipment.

Technical data:

- Max. bevel width:

0 to 29 mm / 0 to 1.14 in < 400 MPa / 58 015 PSI 0 to 25 mm [≈ 1 inch] / 0 to 1 in > 400 MPa /58 015 PSI - Bevel angle:

30°; 45°; 22,5°; 37,5°; 50° (replaceable KIT) - The thickness of the bevel. material:

6 – 60 mm / 0.23 to 2.36 in - Motor: 1500 W

- Feed rate:

1,8 m/min. / 6 ft/min. - Weight:

205 kg / 452 lb - Dimensions:

1010 x 745 x 1326 mm

39.76 x 29.33 x 52.2 in

Description:

- Powerful, stationary bevelling and deburring machine for the efficient bevelling of flat steel, plates and profile material.

- For all carbon steels, cast iron, aluminium and light metal alloys, non-ferrous metals and all cuttable materials.

- The feed permits bevel machining without tight camping of the workpiece.

- The swiveling milling spindle permits a milling angle within a continuous range of 30° – 60°.

- Regulation of feed speed and cutting tool

- Option to buy additional accessories such a milling devide for pipes, table extension left and right (total 2800 mm) with adjustable sidestops left and right

Technical data:

- Bevel angle: Infinitely adjustable within the range from 30°to 60°

- Bevel width: 0 to 30mm ˂ 400 N/mm2 – 0 to 15mm ˃ 400 N/mm2

- Cutter motor: 4kW

- Speed: 0-5500 rpm

- Tool diameter: Ø 94mm

- Number of indexable inserts: 5 pieces

- Thickness of the material: 2 – 100 mm

- Feed motor: 0,45kW

- Feed speed: 0,6-3,5m/min

- Feed motor:400V /50Hz, 3phase, speed 0,6-3,5m/min

- Minimum workpiece dimensions: L=60mm, W=20mm

- Dimensions: 825 x 1200 x 1615 mm

- Weight: 400kg

- Working height: 1,000mm

- Pipe treatment: Ø 102-156mm

Description:

The beveler UZ 50 Triumph – very efficient, unique double sided beveling machine for steel, stainless steel, HARDOX, DOMEX and aluminium (max. width of bevel 62 mm)

3 BEVELERS IN ONE + 3D ADAPTIVE SYSTEM = UNIQUE BEVELLING SOLUTION, MADE BY NKO MACHINES

- automatic feeding, automatic feed speed adjustment with inverter, 0 -1,2m/min

- high speed milling head with very resistant inserts, max. width of bevel 62mm/15°, 50mm/45°

- 15-60° infinitely variable angle, without replacing any parts

- material thickness 7 – 80 mm

- the electric circuit is enclosed in a dust proof box and is equipped with all the safety devices necessary.

- CE conformity declaration

unique MANIPULATOR 3D

- manipulator provides a simple quick turn UZ50 Triumph of 180° to create double sided bevel X K. The operator does not need a crane to rotate the material. There is a significant saving of work time.

- the unique clamping system allows the machine UZ 50 Triumph to be assembled and disassembled (Quick System) within a few seconds without using any tools

EQUIPMENT for bevelling small flat steel

- Equipment is intended for use with the machine UZ50 TRIUMPH

- With the equipment is machine UZ50 TRIUMPH possible use for processing small workpieces

- The machine UZ50 TRIUMPH maintains a continuously adjust the bevel angle between 15°- 60°

Technical data:

- Table size: 700 x 200 mm

- Working height: 914mm

- Weight (without machine): 30kg

- Smallest possible size workpiece: 200 x 100 x 7 mm

- Bevel angle α: 15°-60° infinitely variable

Active Smart Protection for your Triumph against overloading.

The System ASP actively measures the loading of your machine during continuous and demanding operation.The System ASP constantly monitors the working dimensions of the UZ50 machine, the condition of its cutting inserts, the loading of its drive engine and the overall settings of the machine.In the event that an operator uses the UZ50 incorrectly- the machine will say STOP!!!